A blurry field of hear and say

In this article I want to straighten out some of the confusions out there in the marketplace.

Biestmilch is a food supplement, it thus has to be processed according to the nutrition guidelines published by the food and health authorities in the respective countries. Europe has a harmonized codex of rules and regulations. In the industrialized Western world the applied quality criteria don’t differ that much. The globe shrunk also concerning quality precautions. We have two discourses that mingle unluckily when it comes to judging the quality of Biestmilch.

The one is a quality discourse that refers to the safety of the product. For foods in general apply certain hygienic regulations.

The first proposition is, if it comes to the assessment of quality, whether Biestmilch meets the required hygienic standards. Hygiene has nothing to do with the second proposition which is the efficacy of the product. All kind of seals and marks that are issued by institutions and institutes all over the globe refer to the problem of hygiene and contamination, and are meant as a kind of proof that a product is clean and safe.

The other discourse that is swaying around Biestmilch is its efficacy. That the two discourses are treated as one is often done intentionally. This blurry disguise helps to escape arguing about the often doubtful effects of a product. Especially in the field of foodstuff efficacy is hard to prove. I think this may not necessarily be a big issue, as it should remain with the individual to find out what works best for her or him. But what I personally don’t approve is to pretend that quality equals efficacy.

The discourse of efficacy is currently dominated by immunoglobulins, probably due to the fact that they belong to the most familiar molecules among the many immune molecules we know as per today. But more about this later.

Now in the very beginning I want to describe and outline to you, why Biestmilch is a safe product. In the case of new products it is often difficult to differentiate between quality and efficacy, and it’s hard to assess the quality. The following paragraphs want to help you in the decision-making process.

We have two different products, one is made from Biestmilch (bovine colostrum) of German and Austrian cows. Due to the fact that the raw colostrum in Europe is very limited and will for the time being not exceed the laboratory scale, we have another source of raw colostrum which is Arizona.

Most dairies in Arizona are fairly large, keeping between 1,500 to 2,000 cows. Many remain family owned. Like any business dependent on animals or the weather, dairy farming has many risks. In 2009, rising feed costs mixed with a drop in demand overseas and soured the economic outlook for many small dairy farmers. Several dairies that had existed for generations were forced to close their doors. The past few years have seen the industry stabilize somewhat.

Happy Cows from Arizona

Arizona’s climate provides both challenges and benefits to dairy cows. Temperatures are ideal for eight months out of the year. But our extreme heat means cows need special care during the summertime. Mercury in the 90s leads to decreased milk production and potential danger to a cow’s health.

Arizona dairy farmers seem to agree on one point: happy cows give better milk. Therefore, no effort is spared to keep the ladies cool and comfortable. Cows rest in the shade and receive cooling showers twice a day. Misters and state of the art ventilation systems keep air temperatures stable. For nearly two decades, these standard practices have helped dairy farmers—many located in central Arizona—to beat the worst of the summer heat.

Both products, the European and Arizona one, meet the required high standards of quality and don’t differ in efficacy. At least this is what our field experience of more than 13 years tells us. When it comes to efficacy only experience counts.

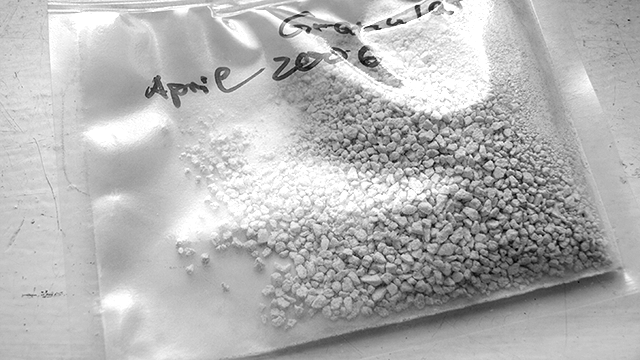

Colostrum powder from Arizona

The cow is the source – our capital since many thousand years

The cow as the basic source of quality Biestmilch has to be healthy and the environment preserved. Cows are very sensitive animals. As soon as the pastures lose the richness of the grass and herbs the quality (here related to efficacy and content of nutrients) and quantity of the biestmilch and milk given go down and so do the nutrients in there. The same happens when the weather is too hot or cold, or an animal suffers from an illness.

Each cow needs the special attention of the farmer every day that quality biestmilch can be guaranteed.

The first milking is always kept for the calf. But the milk cow produces a surplus of biestmilch. Instead of discarding the rest – as it is still the habit in many areas in Europe – it’s collected for further processing.

The first zip of biestmlich connects the offspring with the outside world, nurtures it and switches on all organ systems and endows it with the immunity needed until the offspring built up its own. Its content of fat and other nutrients is high, it contains cells as well as a microbial flora, hormones and thousands of messenger molecules.

Harvested fresh and chilled, never deep frozen

In New Zealand calving is so to speak synchronized all over the Island. Twice a year in spring and in autumn the cows deliver. The farms have got a special aluminum devices for harvesting biestmilch (colostrum, beestings). In this container the fresh biestmilch is chilled to 4 – 7°C until it’s picked up by a special lorry. These lorries are passing by all the farms and collect the fresh biestmilch. It is not deep frozen at any time.

On the contrary, European biestmilch is collected from the farms deep frozen.

Transported to the plant the manufacturing starts right away

First step in this process is the removal of fat. The liquid colostrum is pasteurised to international standards (72°C for 15 seconds). Afterwards the liquid is concentrated by evaporation using the low temperature of 55°C. The skimmed colostrum is then freed from most of its lactose by filter method (ca. 5% remain).

After this procedure the colostrum is spray dried through low temperature processing. Processing at these temperatures has proved to maximise bioactivity. The final raw product, i.e. colostrum powder, is sampled and tested using internationally recognized procedures to meet dairy export standards and all NZL facilities are certified by international ISO*** and HACCP* standards.

The whole manufacturing process is optimized to receive a safe food product with a unique and consistent combination of bioactive molecules.

Packaging of Colostrum powder

Multi-wall paper which incorporates a moisture barrier contains the product within an inner polyethylene bag. No staples or metal fasteners are used.

Storage and Handling of Colostrum powder

Colostrum Powder is kept in cool, dry ventilated storage rooms. Temperatures are kept below 25°C at a relative humidity below 64%. Packages are not in direct contact with walls or floors. Stock is in rotation and used within six months of delivery. Unopened bags have a shelf life of three years.

Manufacture of Biestmilch products from Colostrum powder

Biestmilch finished products are made of semifinished high protein powder, agglomerated colostrum powder. This applies to BIESTMILCH capsules, chewy tablets and the BIEST BOOSTER. All of them are manufactured in Germany. Manufacture is done according to good manufacturing practice (GMP)**.

As in Arizona also here in Germany we follow a strict quality assurance system with in-process control and testing. The aim of the quality assurance system is to guarantee a safe product concerning hygiene, contamination and toxicity.

Furthermore, since 2002 we are working on optimizing the galenics, the texture, the taste and the convenience of our products.

It’s the manufacturing process of the finished product that matters a great deal too when it comes to hold a high quality standard that in this case refers to safety and efficacy.

The kind of packaging of the finished product is of great importance for the safety of a product. Therefore the capsules are in blister packaging, the chewy tablets and the BIEST BOOSTER are sealed in foil. This packaging makes our products moisture resistant and prevents the penetration of microbes and other toxins. All stress tests (temperature, humidity etc.) performed in our laboratory confirmed that a shelve life of 3 years is justified.

The immunoglobulin discourse and efficacy controversy

It became sort of a trend of the Biestmilch sellers to implicit claim the amount of immunoglobulins as criteria of efficacy for Biestmilch. The ranges mentioned reach from 20% to 45%. Of course, immunoglobulins are important components of Biestmilch, but by far not the only molecules that explain the diverse effects of Biestmilch. To only give the amount of a biological molecule is always critical, because the quantity does not say anything about the activity of the molecule. Moreover to compare values without being familiar with the test system is impossible.

There are methods to measure the quantity and others that detect the bioactivity, both are two completely different things. To assess the amount given you need to know whether it is measured in liquid or solid phase.

In the liquid phase the amount will always be lower compared to solid phase when all the moisture evaporated.

Another issue is that Biestmilch is a living substance. The amount of immunoglobulins not only depends on the day of the harvest, but also on the cow’s health condition and the food she gets. Immunoglobulin content can vary from one lot to the other. The smaller the lots the more difficult it is to adjust the content and achieve lot consistency.

To put it in nutshell

Whether Immunoglobulins as currently measured and implied as efficacy criteria are suited to fulfill this role needs further studies and discussion.

Biestmilch solution made from colostrum liquid from Germany and Austria

No doubt that both Biestmilch sources are meeting the safety standards required for foods. I won’t go into a efficacy debate at this point because the controversy applies to Biestmilch (colostrum) per se.

The European product has a different history. Calving is not synchronized like in Arizona. This means that the manufacturer (in our case CPI Ltd) has a contract with the farmers and harvests the Biestmilch on a cow to cow basis. This implies that the colostrum needs to be deep frozen. The farms that meet the criteria for a organic certified raw colostrum are scattered all over the place, and the logistics would be far too costly if picked up at the time of calving.

Another handicap for the collection of sufficient amounts is the fact that in Europe, in our case in the Alps area of Germany and Austria, the herds of cattle are too small. The big herds are mainly industrial livestock farming and don’t meet the criteria that an organic certified product requires. As I already mentioned this manufacturing process is, therefore, at the level of a laboratory scale.

For safety reasons a record of each cow’s Biestmilch is kept. This harvesting and manufacturing process makes it far more difficult to produce consistent lots concerning the amount of bioactive components such as immunoglobulins. The fluctuation range from lot to lot may be wider.

Due to the different scale of production, the process differs. In the factory the deep frozen colostrum is firstly thawed and defatted. This is an easy procedure as the fat is lighter and therefore constituting the first layer of the liquid. Is the fat once removed the casein proteins are precipitated by lab-fermentation (lab is enzyme denaturing this protein fraction). This process is essential, because casein would clog the filter system that then is applied to render the colostrum whey safe. The whey is filtered to make the product safe from a microbial viewpoint. This technique of manufacturing colostrum does not enable the removal of lactose. In the liquid phase the content per 100 ml is 5 – 8%. In the solid phase after freeze drying the content is 30% (we don’t use freeze dried colostrum from this source for our products).

The liquid form is more sensitive than the colostrum powder. When stored cool, dry and protected from light, the shelve life of the solution is 2 years. When the bottle is once opened, it has to be kept in the fridge and consumed within a fortnight.

To put it in a nutshell again:

What happens in this manufacturing process is that the raw colostrum is processed in a way that you have a whey product from colostrum in the end. This whey Biestmilch is then bottled into glass bottles and closed with sealed caps.

The factory manufacturing our Biestmilch solution is working according to GMP** standards too and is inspected by the authorities on a yearly basis. These institutions give the seal of approval „organic certified“. It’s renewed on a yearly basis.

Biestmilch capsules, chewy tablets and the BIEST BOOSTER are developed and manufactured by BIESTMILCH Seven, whereas Biestmilch solution we buy from CPI Ltd also based in Germany.

*HACCP (Hazard Analysis Critical Control Point) is the systematic preventative approach to food safety. It addresses physical, chemical, and biological hazards as a means of prevention rather than finished product inspection. This approach has significant benefits to organisations operating within the food supply chain as it enables them to determine key controls over processes and concentrate resources on activities that are critical to ensuring safe food. Retailers, the food industry and Government in particular are concerned about ensuring that food is produced safely and that the consumer has confidence in the product. This has led to an increase in legislation over time that has focused upon ensuring safe systems of food production. In the UK the 1995 Food Safety Amendment Regulations, for the first time required manufacturers and providers to adopt HACCP to ensure food safety.

**Good manufacturing practices (GMP) refers to guidelines laid down by agencies which control authorization and licensing for manufacture and sale of food and drug product or a medical device, active pharmaceutical products and pharmaceutical excipients. These guidelines are laid down with the intention of providing requirement that a pharmaceutical or a food product manufacturer must meet while manufacturing of drug or a food product or a medical device, which then assures that the product manufactured in compliance with (GMP) practices are of good quality and does not pose any risk or hazard from cross contamination. Good manufacturing practice guidelines provides guidance for manufacturing, testing, and quality assurance in order to ensure that drug product is safe for human consumption.

***ISO International Organization of Standardization

A standard is a document that provides requirements, specifications, guidelines or characteristics that can be used consistently to ensure that materials, products, processes and services are fit for their purpose.

ISO International Standards ensure that products and services are safe, reliable and of good quality.